calsfoundation@cals.org

Brick Industry

Brickmaking in Arkansas began in the early nineteenth century as a much localized industry in which a builder in need of bricks would find a deposit of clay, mold bricks by hand, and fire them in a temporary field kiln, using wood or any other combustible for fuel. In the late nineteenth century, producers who operated as businesses began to appear, and, by 1900, several dozen brick companies operated in the state, with production becoming concentrated in towns where large supplies of clay and/or shale are found. In the twentieth century, brick factories were located in Clarksville (Johnson County), El Dorado (Union County), Fort Smith (Sebastian County), Hope (Hempstead County), Jonesboro (Craighead County), Little Rock (Pulaski County), Malvern (Hot Spring County), Mansfield (Sebastian County), Pine Bluff (Jefferson County), Pocahontas (Randolph County), Wynne (Cross County), and many other places. By the mid-1980s, the only cities with brick plants were Clarksville, Fort Smith, Hope, Jonesboro, and Malvern; as of 2009, only four brick plants operated in the state, all owned by Acme Brick Company.

The Fort Smith Brick Company dates back to the 1840s and was acquired by Acme Brick in 1923, along with a plant at Mansfield. As of 2009, the Fort Smith plant is one of the last two plants in the Acme organization still using periodic kilns. Periodic kilns can produce many colors and blends that cannot be duplicated in the more modern continuous kilns.

In southwest Arkansas, the O’Neal/Gardner family had a 100-year history of brickmaking, mostly in Hope, where they operated Hope Brick Works. James O’Neal had produced bricks in Conway (Faulkner County) and Gurdon (Clark County). His son, Nathaniel Paul (N. P.) O’Neal started making bricks in Gurdon in 1900 and moved to Hope in the 1920s. This company was operated by five generations of the O’Neal/Gardner family. Acme Brick purchased and closed the plant in 2000.

In Jonesboro, Andrew Johnson Patrick was producing handmade bricks from about 1890. He organized Jonesboro Brick Company with several partners and built a modern brick plant. Patrick died only a month after this plant started operations in 1900. Following his death, three generations of the Charles A. Stuck family operated this plant until it closed due to war conditions in 1942. Barton Brick and Southern Brick & Tile also operated in Jonesboro in the early 1900s. In 1946, Ellis R. Wheeler and William F. (Bill) Hall leased the Jonesboro Brick Company plant and re-opened it as Hall-Wheeler Brick Company. Hall sold his interest in 1951, and the name was changed to Wheeler Brick Company, Inc. Wheeler operated this plant until 1966, when a more modern plant was built on the west side of town. This plant underwent major renovations in 1978 and 1994 and was sold to Acme Brick Company in June 2000. Randall Wheeler was president of Wheeler Brick at the time it was sold.

In Clarksville, Earle K. Johnson formed the Eureka Brick and Tile Company, which started production in June 1946. Following his death in 1994, the Johnson family continued operations until Acme Brick bought it in 1999.

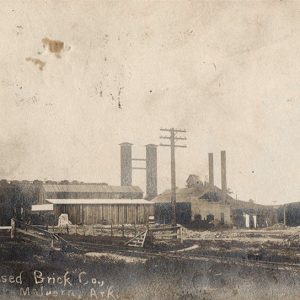

Malvern is by far the leading city in brick production in Arkansas and, at one time, claimed to be the “Brick Capital of the World.” It has been the home of Acme Brick Company, Arkansas Brick & Tile, Atchison Brick Works, Clark Pressed Brick Company (sold to Arkansas Brick & Tile in 1916), and Malvern Brick & Tile. Acme first purchased property at Malvern in 1919 and began negotiations to purchase Arkansas Brick & Tile. Malvern Brick & Tile was started in 1925 and, at one time, had a line of bricks in colors such as blue, green, pink, and yellow. Other companies sprayed the color onto the face of the brick, but Malvern Brick used stains that colored the whole body of the brick. It is not likely that any other company produced blue and green bricks with through-the-body colors. Malvern Brick was purchased by Acme in the late 1970s.

In 1981, Acme started an annual event called Brickfest to showcase the industry to the general public. Events include a five-kilometer run, arts and crafts displays, musical concerts, a brick-throwing contest (judged by accuracy and distance), a three-on-three basketball tournament, and a “brick car” derby. It is held the last full weekend in June of each year.

Because the mineral content of clay and shale varies from location to location, it is very difficult for a plant in one place to make products identical to those in another place. This makes each plant’s products unique. A good brick dealer can usually tell at a glance the source of a brick.

The high cost of automated equipment and the difficulties brought on by a highly regulated economy have resulted in most of the smaller companies being sold to larger companies. By 2009, Acme Brick Company, which is the largest American-owned brick company, had become the only operator of brick factories in Arkansas, with a total of four plants operating in Fort Smith, Jonesboro, and Malvern. In Malvern, the plants are Ouachita (at the former site of Malvern Brick) and Perla East Gate. The modern brick industry employs automated machinery and computer-controlled robots to create face brick in a multiplicity of colors, blends, and sizes for the commercial and residential markets.

For additional information:

Lehr, Edwin E. Colossus in Clay: Acme Brick Company: The Story of the Largest American Owned Brickmaker. Virginia Beach: The Donning Company Publishers, 1998.

Wheeler, Randall. “The History of Brickmaking in Jonesboro, Arkansas.” Craighead County Historical Quarterly 31 (January 1993): 3–8.

Randall Wheeler

Jonesboro, Arkansas

Comments

No comments on this entry yet.