calsfoundation@cals.org

Industrial Sand Mining

Industrial sand is a term normally applied to high-purity silica sand products with closely controlled sizing. Industrial sand is a more precisely sized and shape-graded product than common sand used as aggregates in construction materials, such as concrete and asphalt. Typically, sand is composed predominantly of quartz (SiO2), and, in the case of industrial sand, the shape, size, and composition of the grains are important to determining suitable uses for the product. Sizing of industrial sand is typically done by screening and air sorting of a dried product. The term “sand,” as used by geologists, generally refers to individual grains that range in particle size from 0.00246 to 0.0787 inch (0.0625–2.0 millimeter) in diameter. This grain size ranges from just above silt to just below gravel. Industrial sand sizes are restricted in range, depending on ultimate use. Sand-sized mineral particles compose one of the most common sedimentary rocks—sandstone.

Uses

Industrial sand has many industrial uses, including being the primary component in glass manufacture, as foundry sand for metal casting, metallurgical use as a flux, as a chemical source for silicon-based products, as an additive to many building materials, in ceramics applications such as glazes and body additives, in water filtration media, in oil and gas production as hydraulic fracturing media (frac sand), and even in recreational activities, including sand traps on golf courses.

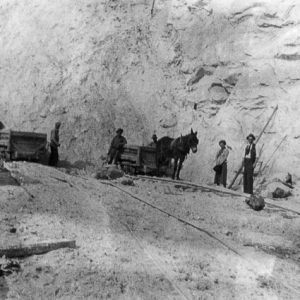

Mining of Industrial Sand in Arkansas

Arkansas has several mining operations involved with the production of industrial sand. Unimin Corporation began operating in Guion (Izard County) and produces a variety of sizes of silica sand products from the St. Peter Sandstone of Ordovician age. Mining is done by room-and-pillar method, whereby rooms are cut into the area being mined, with pillars left standing to support the mine. The sand-bearing formation consists of very pure silica sand that is highly friable, a distinct advantage for disaggregating the sand into its individual grains. Once dried, the loose sand is air classified—that is, sorted into various desired sizes. The sand is not crushed during processing. The products are marketed for glass manufacture, foundry sand, and hydraulic frac sand. Arkhola Sand & Gravel Company’s operation, located in Sebastian County on the Arkansas River, began operation in the early 1900s. In this mining operation, industrial sand is dredged, cleaned, acidized, dried, and sized. Besides major markets in common construction sand, the industrial sand component is marketed as hydraulic frac sand. A third mine, operated by Delta Company, opened in 2007 in eastern Pulaski County, where sand is open-pit-mined from Quaternary deposits adjacent to the Arkansas River. The product from this mine is marketed as hydraulic frac sand.

Traditional markets for industrial sand from Arkansas have long existed for the manufacture of glass and foundry sand. Recent drilling activity since 2006, related to the Fayetteville Shale, created a new and important market for local production of specialty sand as a hydraulic fracturing media. Until local production began, frac sand was being transported from Texas and other states, the cost of shipping being a major consideration of this material in bulk. Several sources of suitable sand in Arkansas were investigated by industry during the start of the Fayetteville Shale Play, and local active deposits were reevaluated. This resulted in production of frac sand from two existing mining operations, as well as the opening of a new mine. Frac sand is injected into fractures opened within the Fayetteville Shale formation to prop the fractures open so gas can escape.

In 2009, the mine near Guion had been operated continuously for more than ninety years and operated under several ownerships before being purchased by Unimin Corporation, which became Covia in 2018.

For additional information:

Arthur, J. D., Bohm, B., Coughlin, B. J., and Lane, Mark. “Hydraulic Fracturing Considerations for Natural Gas Wells of the Fayetteville Shale.” Tulsa, OK: ALL Consulting, 2008. Online at http://www.all-llc.com/publicdownloads/ALLFayettevilleFracFINAL.pdf (accessed March 9, 2022).

Dunkin, D. D. “Geology and Non-Metallics—Mining and Preparation of St. Peter Sandstone in Arkansas (with Discussion).” Littleton, CO: American Institute of Mining Engineers, 1928.

Franco, Cheree. “Controversial Frac Sand Mining Comes to Arkansas.” Arkansas Times, January 23, 2013, pp. 14–17, 19–21. Online at http://www.arktimes.com/arkansas/controversial-frac-sand-mining-comes-to-arkansas/Content?oid=2638138 (accessed March 9, 2022).

J. Michael Howard

Mabelvale, Arkansas

That is now Limedale property (2024). It is being operated by Thomas Crushing out of Kansas City, Missouri. Rail cars are loaded onsite and transported to Limedale in between Cushman and Batesville to be processed.

We have noticed one of the mines near Guion at the junction of Lafferty Road and River Road has opened back up. Any information is appreciated.