calsfoundation@cals.org

Gypsum Mining

Gypsum is a mineral (CaSO4·2H2O) that occurs in nature as both a mineral and, when in massive form, a rock. Massive deposits are present as sedimentary beds of varying thickness in the subsurface within the Trinity Group in southwest Arkansas. Gypsum beds dip gently to the south, being part of the Early Cretaceous Gulf Coast series of sedimentary deposits. The gypsum-bearing De Queen limestone member of the Trinity Group is exposed in a narrow belt extending from the Little Missouri River in Pike County westward through Howard and Sevier counties, and dips gently to the south. The thickest single gypsum bed (at twelve feet) is at Plaster Bluff (Pike County). A significant operation near Briar (Howard County) mines five beds of massive gypsum with an aggregate thickness of as much as twenty feet. One variety of gypsum, satin spar, is interlayered with clay units as thin layers (0.5 to 2.5 inches in thickness), both above and below the five minable layers of alabaster, another variety of gypsum. However the satin spar is considered waste because it is too thin to be recovered economically.

To be of commercial value, the massive rock gypsum must meet certain quality specifications and be close enough to the surface to be mined by open-pit methods. It is present as repetitive beds, and mining takes advantage of this “stacking” of beds. Gypsum has several commercial uses, the most important in Arkansas being for the manufacture of wallboard (sheetrock). Other uses include additives to cement as a retardant agent (slowing the crystallization time of cement in concrete). Use as sheetrock involves drying and calcining of gypsum rock, grinding, and remixing with water. The gypsum slurry is then extruded between paper backing, and, after setting up, sheets are cut to specific sizes. Drying in large gas-fired ovens cures the wallboard. The final product is shipped by either truck or rail from the plant facility.

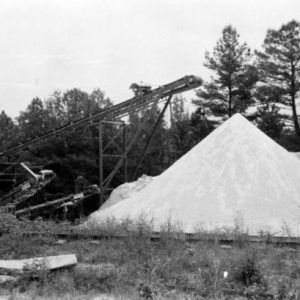

Mining

Gypsum was first mined in Arkansas in 1922, with continuous production starting in 1936. The local Highland Gypsum Company operated a small mine near Highland (Pike County) beginning in the 1960s. The mined material was used locally as a cement additive. C. W. Harrison of Oklahoma bought the Highland mine in the early 1990s; it is now closed and reclaimed. By 1961, yearly production in the state had risen to 166,698 tons. Dierks Forests, Inc., opened the Briar Gypsum plant in Howard County in 1963. Early on, this mining and manufacturing facility was one of the world’s ten largest producers of wallboard. The property has changed ownership several times, with owner/operators having included Weyerhaeuser Company, James Hardie Gypsum, Boral, BPB Gypsum, and (as of 2010) CertainTeed Company, a wholly owned subsidiary of Saint Gobain. Saint Gobain is a major international company with world markets in the construction products, innovative materials, and packaging businesses.

Historic activity in the 1980s and 1990s resulted in more than 1 million cubic yards of overburden typically being removed and more than 600,000 tons of gypsum mined annually. From this, more than 600 million square feet of wallboard were produced. In late 1997, under James Hardie Gypsum, a major expansion of the facility doubled the plant’s wallboard manufacturing capability. Its capacity of 1.4 billion board feet annually makes it the world’s largest wallboard production plant. The mining property and plant are now owned by CertainTeed. Since the start of the housing recession in late 2008, the plant operation continued mining of gypsum and production of wallboard but on a limited schedule, awaiting an increase in demand for their product. Product from the CertainTeed operation is marketed within the central and southeastern U.S. markets. When at full production, this gypsum operation employs more than 200 full-time miners, plant workers, and engineers.

Recent CertainTeed exploration and land acquisition has been directed toward securing additional reserves of gypsum for the levels of production projected through the 2030s.

For additional information:

Dane, C. H. Upper Cretaceous Formations of Southwestern Arkansas. Arkansas Geological Survey Bulletin 1. Little Rock: Arkansas Geological Survey, 1929.

“Industrial Minerals.” Arkansas Geological Survey. https://www.geology.arkansas.gov/minerals/industrial.html(accessed February 9, 2022).

Miser, H. D., and A. H. Purdue. Geology of the DeQueen and Caddo Gap Quadrangles, Arkansas. U.S. Geological Survey Bulletin 808. Washington DC: U.S. Geological Survey, 1929.

Pierson, F. L. “The Weyerhaeuser Gypsum Mining Operation at Briar, Arkansas.” In Arkansas-Texas Economic Geology Field Trip. Arkansas Geological Commission Guidebook 74-1. Little Rock: Arkansas Geological Commission, 1974.

Stroud, R. B., R. H. Arndt, F. B. Fulkerson, and W. G. Diamond. Mineral Resources and Industries of Arkansas. U.S. Bureau of Mines Bulletin 645. Washington DC: U.S. Department of the Interior, 1969.

J. Michael Howard

Mabelvale, Arkansas

Comments

No comments on this entry yet.