calsfoundation@cals.org

Cotton Gins

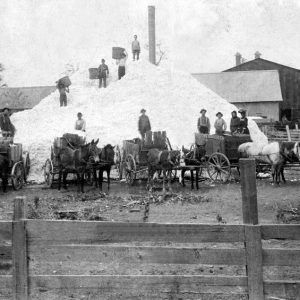

The cotton gin (from the word “engine”) is a device that separates cotton fibers or lint from the seeds and other impurities (called gin trash) of harvested cotton. The “ginned” cotton is compressed into bales that are then sent to mills that spin it into yarn or thread. The building that houses the ginning and baling equipment is sometimes referred to as a ginnery. Cotton gins are an essential component of the cotton industry in Arkansas.

There are two types of gin: roller and saw. The roller or churka gin has been in use for centuries and employs counter-rotating rollers to expel seeds while allowing the fiber to pass through the rollers. Roller gins are used primarily on long-staple (or -fiber) varieties of cotton such as Sea Island and Pima. Although roller gins are less expensive and not as complex as the saw-type gin, they are typically less productive. Arkansas produces only the shorter-staple Upland-type cotton.

The more common type of gin employs a series of circular saw blades that pull the cotton fibers through fixed ribs. The seeds are blocked by the ribs, fall away from the fiber, and are collected for further processing. The earliest version of this type of gin was invented by Eli Whitney in 1793. It is rumored that he came up with the idea from seeing a cat reaching through the slats of a chicken coop.

The introduction of this labor-saving device led to an enormous increase in cotton production in the early nineteenth century in southern states where growing conditions were favorable. This, in turn, led to the increased dependence on slavery and the growth of plantation agriculture. Cotton exported to the mills of England was a major raw material of the Industrial Revolution. After the Civil War, emancipated formerly enslaved people often remained on the same plantations and provided labor either for daily wages or as tenant farmers or sharecroppers.

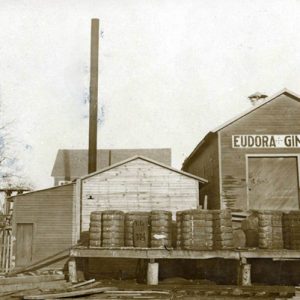

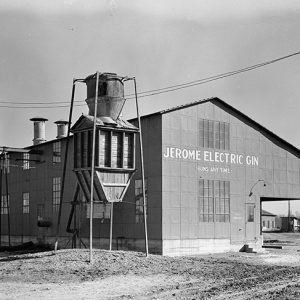

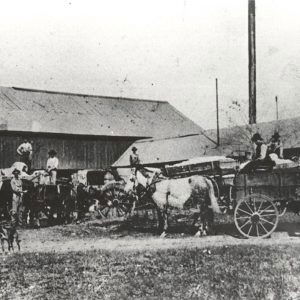

Early gins were powered by animals, typically mules, as well as water wheels, and eventually steam engines. By the early twentieth century, gasoline engines replaced most steam engines, and once electricity became available, electric motors powered the gins. Modern gins remove other types of impurities found in freshly harvested cotton, such as leaves, sticks, unopened boles (motes), and rocks. During the period when laborers were paid by the pound to pick cotton, a few rocks in the bottom of the sack benefited the picker but could seriously damage the gin. Cotton in Arkansas is now picked using mechanical harvesters. The introduction of mechanical pickers is cited as one contributing factor of the “Great Migration” of laborers from Arkansas and other southern states to northern cities.

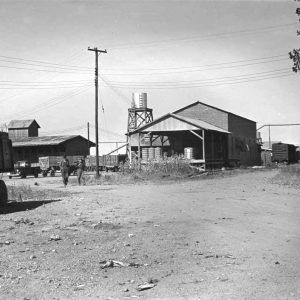

Cotton gins operate for only a few months each year, typically September through December, but often run day and night during those months. Safe working conditions are common in modern times, but that was not always the case. Open fan belts and drive shafts once caused serious injuries and death. Fingers lost in placing the steel bands on bales was not uncommon. Fires were a constant threat, and steam was often used to reduce the risk of static sparks igniting the cotton as it was being processed. Dust and gin trash were often blown out into the nearby area unfiltered, causing air quality issues. Modern gins are required by law to have safer working conditions. Dust-collection systems called cyclones are now used to maintain air quality.

Fiber was the primary product from ginned cotton, but the seeds played an important role as well. Over half the weight of raw cotton is seed and, at one time, was considered waste. Producers eventually found uses for the seeds, which included animal feed, fertilizers, and cellulose for a range of manufactured products. Cottonseed oil from crushed seed is another major byproduct from the ginning operation. Cooking oils derived from cottonseed oil became popular in the twentieth century and include such products as Crisco, oleo margarine, and compound lard. Oil mills operate in several Arkansas cities, including Little Rock (Pulaski County), Pine Bluff (Jefferson County), Helena-West Helena (Phillips County), and Osceola (Mississippi County). Often the farmer’s fee to the ginner was the seed itself. The gin operator would then sell the seed to the oil mills. Competition among seed sellers and buyers was fierce and sometimes underhanded. The situation became serious enough that congressional antitrust hearings were held to address the problem in the 1930s.

A bulletin on cotton production and distribution prepared by the Department of Commerce for the years 1914–1915 showed Arkansas as having 1,880 active ginneries and 156 inactive. There were also forty-three oil seed processing mills in the state. At that time, cotton was grown in every county in the state except the four most northwestern counties.

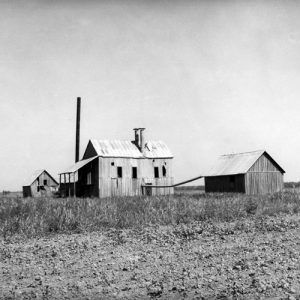

By 2022, there were approximately 235 gins in Arkansas, including thirty active or recently active gins. Many of the remaining gin structures have been repurposed as farm equipment storage sheds, private businesses, event centers, and residences. There are many that are completely abandoned yet, unlike their wooden predecessors, remain standing because of the long-term strength of their iron and steel frameworks. A non-working steam-powered gin has been restored and is on view at the Plantation Agriculture Museum in Scott (Pulaski and Lonoke counties). There are multiple cotton gins in Arkansas on the National Register of Historic Places, including the Weldon Gin Company Historic District in Weldon (Jackson County).

Gins were typically located along transportation routes such as navigable waterways and railroads. Large warehouses equipped with powerful compresses and fire protection systems were constructed, often with federal assistance, in major ginning towns. Those compresses reduced the size of the baled cotton to maximize the number that could be loaded onto railcars. Modern gins compress the bales to the now standard size of 54″x20″x33″ and a weight of about 480 pounds. Cotton bales are transported to spinning mills and docks for export using trucks.

For additional information:

Britton, Karen Gerhardt. Bale o’ Cotton: The Mechanical Art of Cotton Ginning. College Station: Texas A&M University Press, 1992.

Fletcher, Sonja Parker Conley. “Guy Conley’s Cotton Gin—Paris, Arkansas.” Wagon Wheels 26 (Spring/Summer 2006): 15–18.

McCourt, R. C. “Down Memory Lane: A Trip to the Cotton Gin.” White County Heritage 28 (1990): 75–77.

May, Milton D. “Rose Bud Cotton Gins.” White County Heritage 43 (2005): 47–53. Online at https://scholarworks.harding.edu/wchs-heritagejournal/26/ (accessed January 10, 2024).

Morrison, Larry. “The Bell-Lampkin Cotton Gin.” Ouachita County Historical Quarterly 25 (Fall 1993): 20–25.

Rogers, Sam L. “Cotton Production and Distribution, Season of 1914–1915.” Bulletin 131, Department of Commerce, Bureau of the Census. https://www2.census.gov/library/publications/decennial/1910/bulletins/agriculture/131-cotton-production-and-distribution-season-of-1914-15.pdf (accessed July 12, 2022).

Stanley, Bonnie Jean. “The Cotton Gin.” The Heritage 12 (1985): 39–42.

Williams, Claire. “As Cotton Acres Shrink, Gins Vanish in State.” Arkansas Democrat-Gazette, May 22, 2016, pp. 1G–2G. Online at https://www.arkansasonline.com/news/2016/may/22/as-cotton-acres-shrink-gins-vanish-in-s/ (accessed July 12, 2022).

Wrenn, Lynette Boney. Cinderella of the South: A History of the Cottonseed Industry 1855–1955. Knoxville: University of Tennessee Press, 1995

Andy Feinstein

Fayetteville, Arkansas

Comments

No comments on this entry yet.